operations & supply chain improvement

saving you time, money, energy and wasted effort

Drawing from our on-the-ground experience and proven tool-kit, Charles Edwards saves you time by helping you solve operational and supply chain challenges in a shorter time frame. We also save you money by helping improvement investments yield performance improvements that can't be achieved by brute force alone. We provide not only expertise but also bandwidth to execute transitions to a productive routine that you know will deliver results - and not suck your team into a vortex in the process. Lastly, we save you time and effort through taking the guesswork out of improvement efforts.

Put our independent & practical perspective to work for you

- Charles Edwards brings an independent viewpoint, giving you perspective beyond your personal networks and day-to-day operations.

- We also bring experience - decades of it - including that of our extended network - to your business challenges.

- We provide actionable solutions, the specifics you need to decide not only where to make changes but how.

MAXIMIZE PERFORMANCE WHILE MINIMIZING DISRUPTION

Rapid Assessment

Improvement & Restructuring

Rapid Assessment

Charles Edwards can rapidly assess the state of your operations and supply chain activities using a focused approach that brings clarity while not overburdening your team.

Due Diligence

Improvement & Restructuring

Rapid Assessment

Charles Edwards thoroughly and independently evaluates processes, people, and systems to identify risks as well as capability, cost, delivery, and supplier challenges – and opportunities.

Improvement & Restructuring

Improvement & Restructuring

Improvement & Restructuring

Many of us have had to take drastic actions in response to the COVID crisis and will have to address capability shortfalls when conditions improve. Charles Edwards quickly develops and effectively implements achievable improvement plans that get results – even in today’s resource constrained environment.

Tailored Solutions

We know that each company is unique.

- Our approach is not to arrive with a prepackaged solution to all problems.

- Instead we use a combination of data driven analysis and firsthand observations to quickly identify root causes to operational problems.

- Once identified, we develop solutions considering the client’s culture to drive process improvement with the least amount of disruption.

IMPROVEMENT EXPERTISE IN multiple areas

Charles Edwards has worked with all kinds of manufacturing operations - assemblies and piece parts - with all kinds of materials - metal, composites, and plastics.

We know that assembly operations face different challenges from those of manufacturing. Charles Edwards has worked extensively with large and small assembly production to improve throughput, reduce variability, and ultimately improve delivery, save money and lower inventory.

Composites present a special challenge as their unique operations and they don’t fit well with ERP systems. Charles Edwards has specific expertise and experience with composite operations, both large and small.

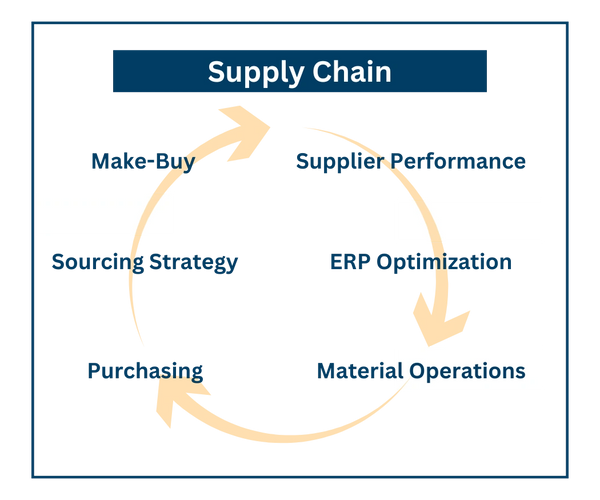

From Make-Buy through sourcing strategy to managing suppliers and material operations, Charles Edwards can help you assess, structure, and more effectively execute supply chain activities.

Your systems are critical to supply chain effectiveness. Our team can help you understand the capabilities and work with the limitations of your existing ERP on supply chain effectiveness as well as help you prepare for full ERP implementations.

Selected completed projects

Operations Due Diligence Of A Composite Parts Manufacturer

Rapid assessment of a composite parts maker to outline a pre-sale improvement plan to reduce persistent inventory increases

(Private Equity Investor)

Inventory Reduction Project

Reduced Inventory 37% and increased on time delivery from to 95% from 65% over a seven month period. Business has since sustained these levels.

(Private Equity-Owned Tier 2/3 Machining and Assembly Shop)

Parts Outsourcing / Cost Reduction Project

Achieved 28% reduction in shipset material cost without impacting program deliveries by re-sourcing 20,000 part numbers.

(Major Tier 1 Aerostructures Supplier)

Supply Chain Strategy

Evaluated the market dynamics of six key spend categories to identify spend reduction and re-sourcing opportunities.

(Equipment Systems OEM)

Composite Parts Manufacturer Operations Due Diligence

Performed operations due diligence of six facilities in three different locations to identify valuation risks, road blocks to growth, and improvement plans.

(Private Equity Investor)

Acquisition Integration Management

Managed due diligence and integration teams to identify deal synergies, developed the plans to capture them, and realize the planned benefits.

(Tier 3 Precision Parts Manufacturer)

Facility Move Parts Outsourcing

Outsourced 23,000 part numbers within 540 calendar days in order to ensure supply during a major plant move.

(Major Tier 1 Aerostructures Supplier)

How can we help you?

Titanium Global Market Outlook & Supply Risk Assessment

Our latest insights to help your business

Cookie Policy

This website uses cookies. By continuing to use this site, you accept our use of cookies.